PRESSED GRATING

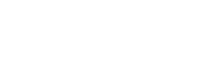

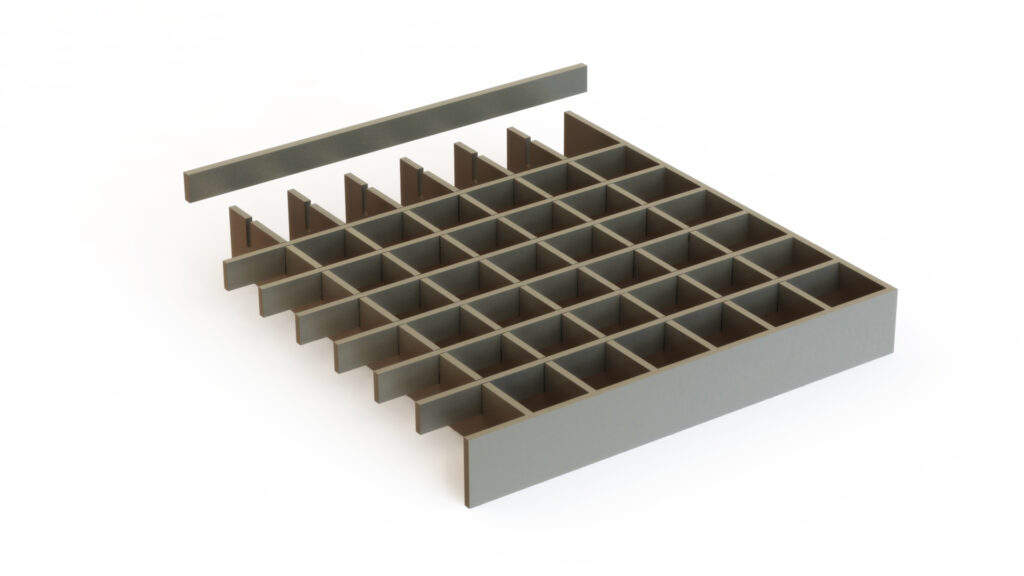

Grating with the supporting bar different from the separating bar. The load capacity remains the same, however the weight/m2 of the grating is lower and consequently the cost of manufacturing and galvanizing is also lower when compared to grating with identical bars.

BAR X BAR GRATING (DIFFERENT BARS)

| REFERENCE | MESH | BEARING | SEPARATOR | LATERALS |

| BB33.33-B25.2-B10.2 | 33×33 | 25×2 | 10×2 | 25×2 |

| BB33.33-B25.3-B10.3 | 33×33 | 25×3 | 10×3 | 25×3 |

| BB33.33-B30.2-B10.2 | 33×33 | 30×2 | 10×2 | 30×2 |

| BB33.33-B30.3-B10.3 | 33×33 | 30×3 | 10×3 | 30×3 |

| BB33.33-B40.2-B10.2 | 33×33 | 40×2 | 10×2 | 40×2 |

| BB33.33-B40.3-B10.3 | 33×33 | 40×3 | 10×3 | 40×3 |

| BB33.33-B50.2-B10.2 | 33×33 | 50×2 | 10×2 | 50×2 |

| BB33.33-B50.3-B10.3 | 33×33 | 50×3 | 10×3 | 50×3 |

| BB33.33-B60.2-B10.2 | 33×33 | 60×2 | 10×2 | 60×2 |

| BB33.33-B60.3-B10.3 | 33×33 | 60×3 | 10×3 | 60×3 |

Other references available on request.

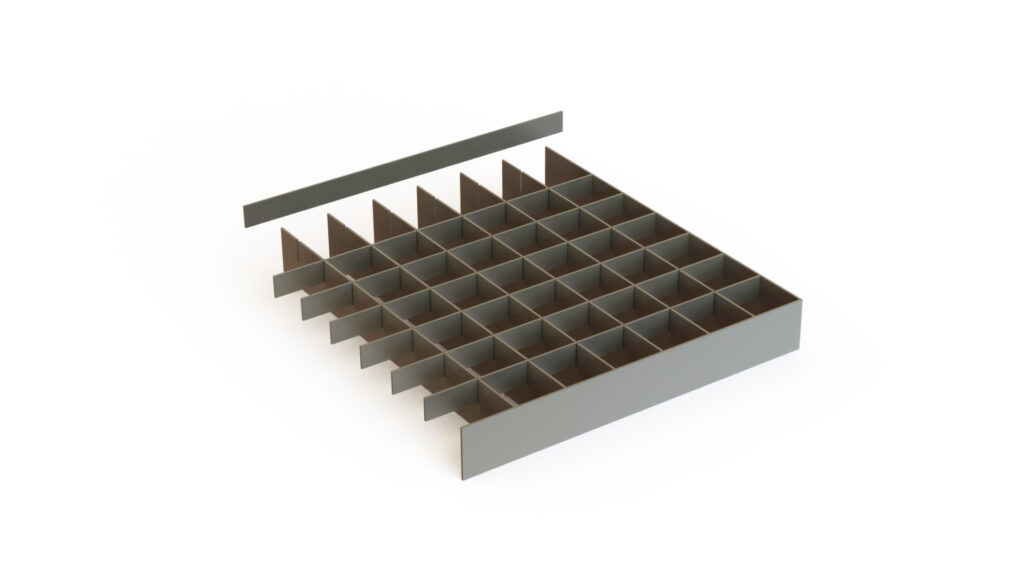

Grating with bearing bars and equal separators. The load capacity remains the same as different bar grating. This type of grating is more used for partitions or other applications where there is a need to have an identical material on the upper and lower sides.

BAR X BAR GRATING (EQUAL BARS)

| REFERENCE | MESH | BEARING | SEPARATOR | LATERALS |

| BB33.33-B25.2-B25.2 | 33×33 | 25×2 | 25×2 | 25×2 |

| BB33.33-B25.3-B25.3 | 33×33 | 25×3 | 25×3 | 25×3 |

| BB33.33-B30.2-B30.2 | 33×33 | 30×2 | 30×2 | 30×2 |

| BB33.33-B30.3-B30.3 | 33×33 | 30×3 | 30×3 | 30×3 |

| BB33.33-B40.2-B40.2 | 33×33 | 40×2 | 40×2 | 40×2 |

| BB33.33-B40.3-B40.3 | 33×33 | 40×3 | 40×3 | 40×3 |

| BB33.33-B50.2-B50.2 | 33×33 | 50×2 | 50×2 | 50×2 |

| BB33.33-B50.3-B50.3 | 33×33 | 50×3 | 50×3 | 50×3 |

| BB33.33-B60.2-B60.2 | 33×33 | 60×2 | 60×2 | 60×2 |

| BB33.33-B60.3-B60.3 | 33×33 | 60×3 | 60×3 | 60×3 |

Other references available on request.

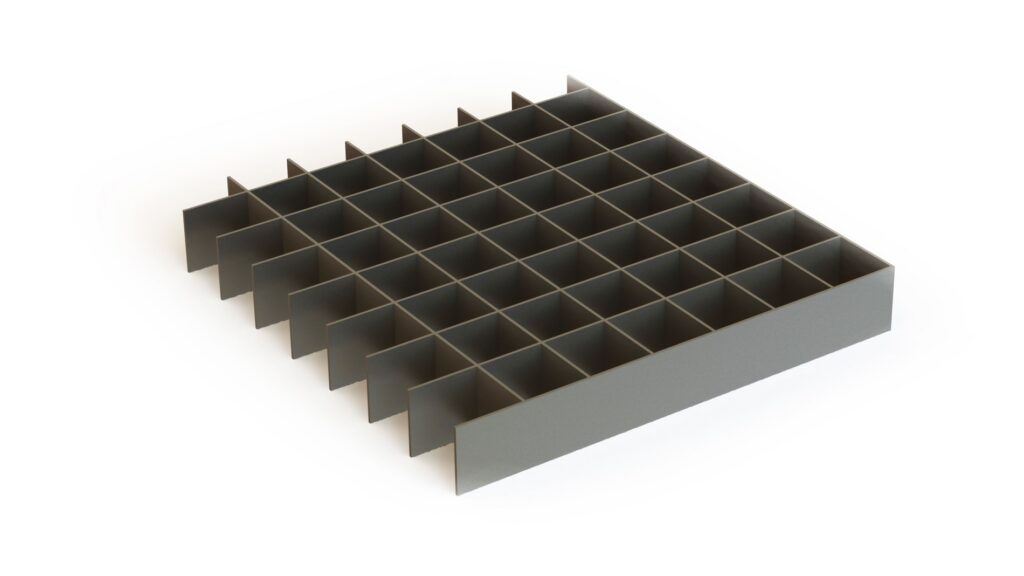

Grating whose mesh dimensions ensure the filtering of spheres equal to or greater than 20 mm, being suitable for the 20 mm sphere test.

BAR X BAR GRATING (APPROPRIATE FOR 20mm BALL TEST)

| REFERENCE | MESH | BEARING | SEPARATOR | LATERALS |

| BB21.22-B25.2-B10.2 | 21×22 | 25×2 | 10×2 | 25×2 |

| BB21.22-B25.3-B10.3 | 21×22 | 25×3 | 10×3 | 25×3 |

| BB21.22-B30.2-B10.2 | 21×22 | 30×2 | 10×2 | 30×2 |

| BB21.22-B30.3-B10.3 | 21×22 | 30×3 | 10×3 | 30×3 |

| BB21.22-B40.2-B10.2 | 21×22 | 40×2 | 10×2 | 40×2 |

| BB21.22-B40.3-B10.3 | 21×22 | 40×3 | 10×3 | 40×3 |

| BB21.22-B50.2-B10.2 | 21×22 | 50×2 | 10×2 | 50×2 |

| BB21.22-B50.3-B10.3 | 21×22 | 50×3 | 10×3 | 50×3 |

| BB21.22-B60.2-B10.2 | 21×22 | 60×2 | 10×2 | 60×2 |

| BB21.22-B60.3-B10.3 | 21×22 | 60×3 | 10×3 | 60×3 |

Other references available on request.

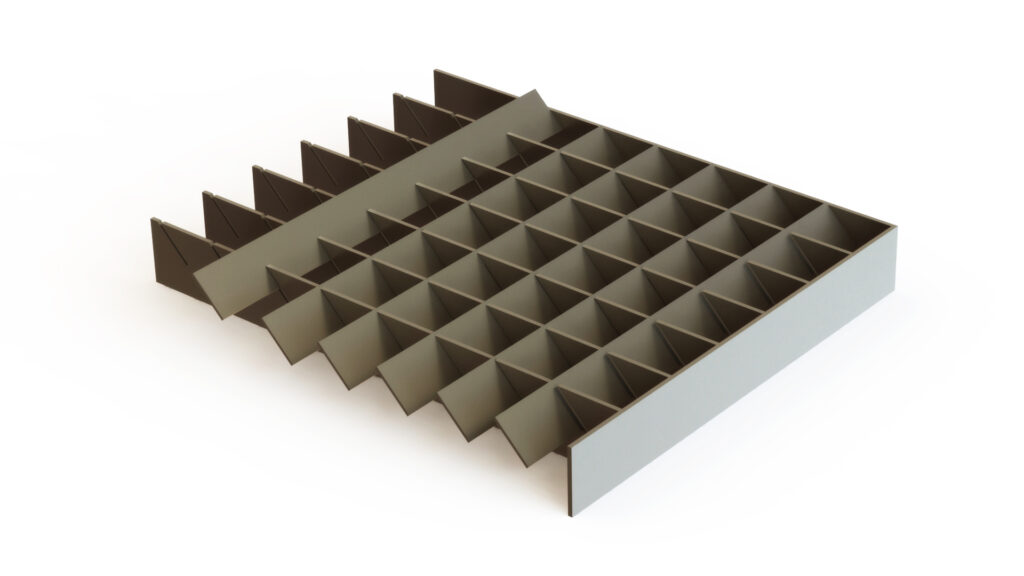

The blind-type grating is characterized by having secondary bars arranged at an angle of 15, 30 or 45 degrees. The secondary bars arranged in an angular manner, allow you to create different transparency effects, cut wind and rain, reduce and control solar incidence on buildings, among other applications. This type of grating is widely used for exhaust grilles, facades, bridge floors, walkways and ceilings.

The mechanical grating is intended to support large loads. This type of grating is made up of wider and thicker bars to maximize its load capacity.

We are able to design and manufacture gratings to support loads in excess of 60 tons/m2.

We produce according to the design of each client and provide technical support during the sizing process.