Types of Grating

Existing on the Market

March 2024

Several different types of grating are available all over the world, for different applications according to the needs of each project.

The most common types of grating are:

Eletrowelded Grating

Consisting of the crossing between bars and rods through contact fusion. The rods may be smooth or twisted and the bars may also be smooth or serrated. The serrated bars and twisted rods give the railing a greater anti-slip effect.

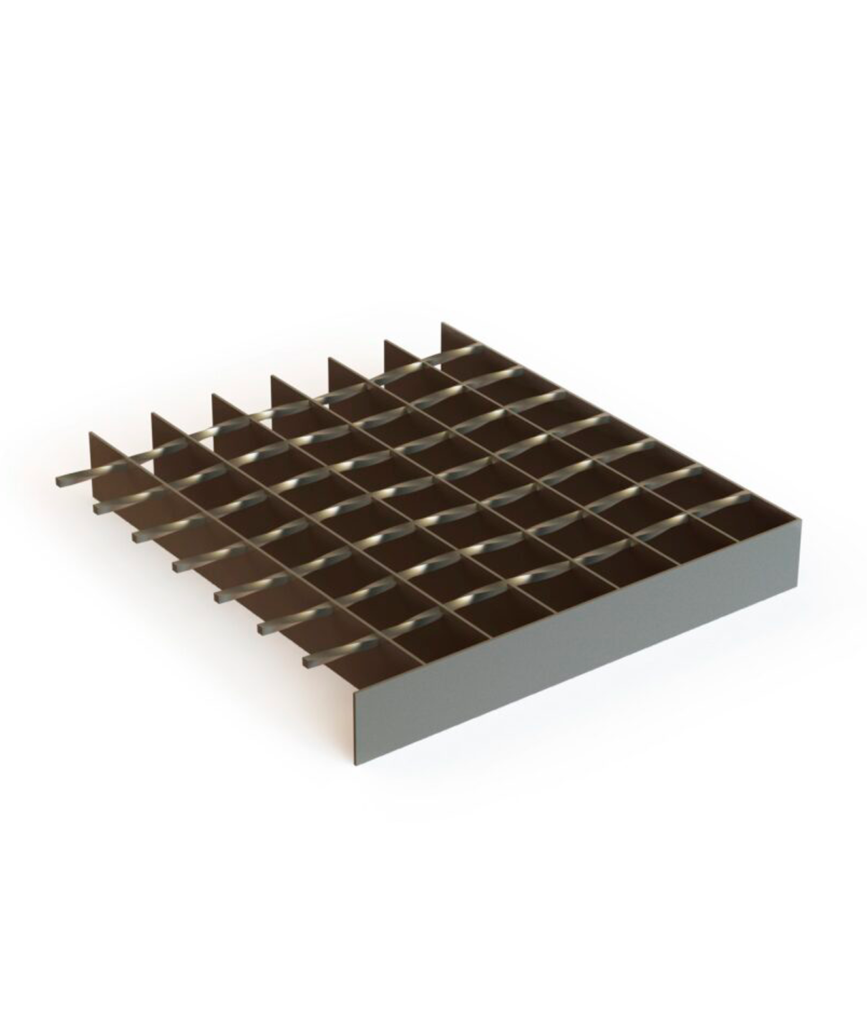

Pressed Grating

Consisting of the crossing of bars with bars through a pressing system that fixes the bars under pressure. The bars may be smooth or serrated. Being serrated allows for a greater anti-slip effect on the railing. The pressing grating manufacturing system is most used for the production of light gratings, with thinner thicknesses. Typically up to 4.0mm. The Mechanical manufacturing system is used for gratings supporting large loads and requiring higher bar thicknesses.

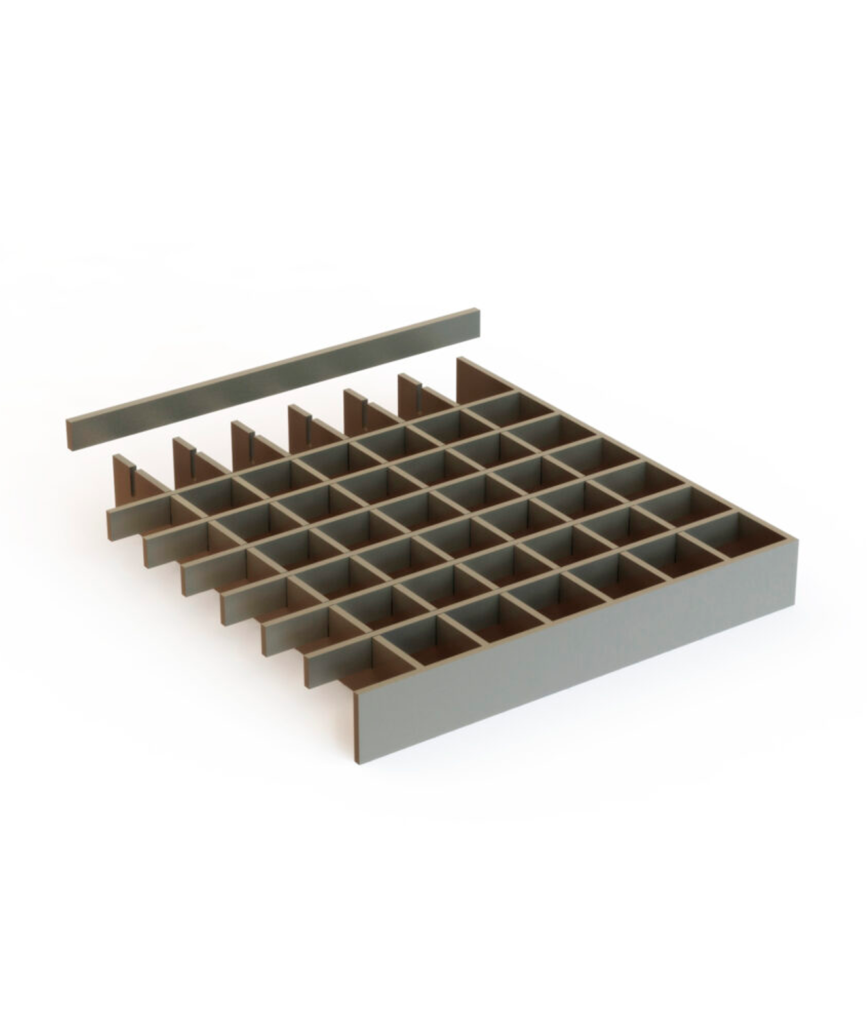

Mechanical Grating

Used to support large loads, this type of grating is produced with wider bars and thicker bars that can start at 5.0mm and go up to 20.0mm. In these cases, manufacturing is resorted to using a mechanical process, which is more manual than the previous two and consists of fitting and welding the bars more manually, using deeper and longer welds to guarantee connections that are strong enough for the loads to be handled. to support.

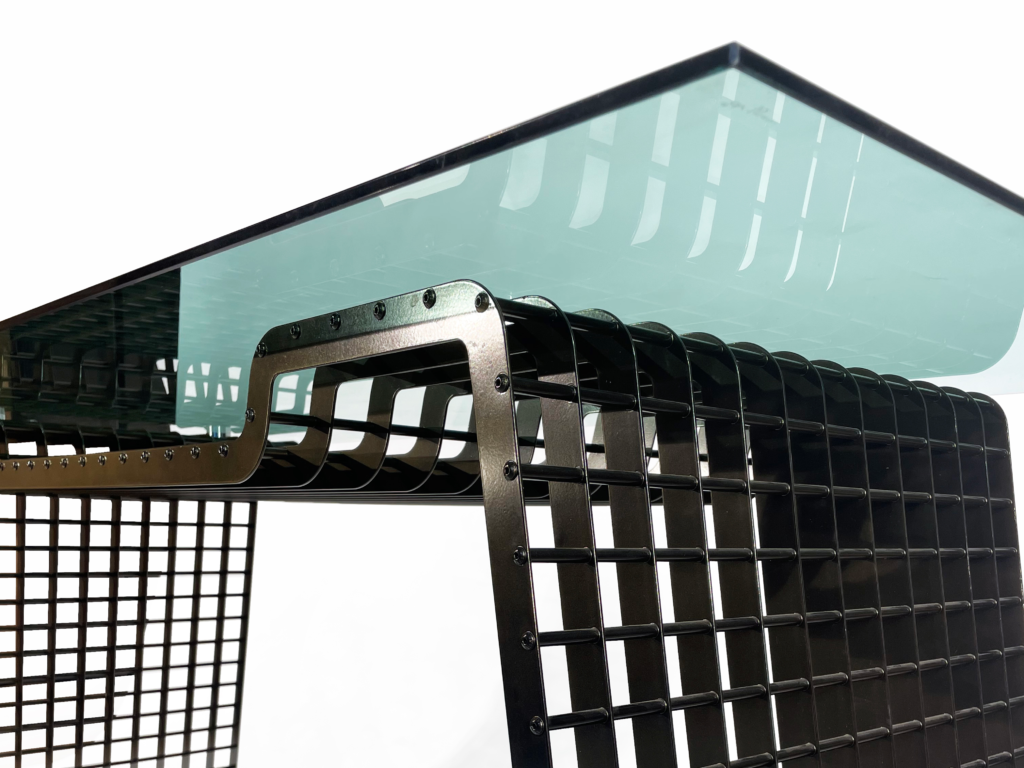

In addition to the flat grating, there is also the three-dimensional grating developed by the Portuguese company Cobermaster and which has wider applications, particularly in architecture and interior decoration.

The three-dimensional grating can be produced using a welding process, such as electro-welded and mechanical grating. Cobermaster has also developed an innovative process for manufacturing three-dimensional gratings by fitting that completely excludes the use of welding, thus guaranteeing a perfect, millimetric finish.