Three-Dimensional Grating

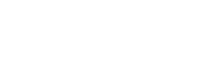

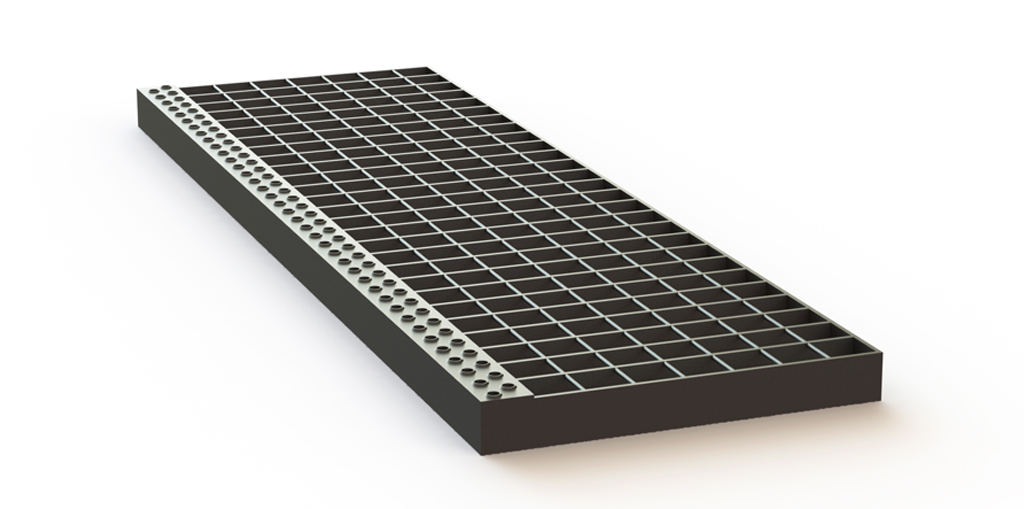

Three-Dimensional Grating By Cobermaster Concept October 2024 Grating is a material that has existed for more than half a century in the form of a plate. It is generally used on oil and industrial platforms to access machines and technical areas. Our R&D team decided to take this industrially used material and transform it into a type of grating with premium finishes and three-dimensional shapes that we are currently using in solutions for architecture and interior decoration! BOOKCASE Cabinet | ECLIPSE Mirror | BLACK Center Table | STUDIO Floor Lamp To this end, we adapted this material from an aesthetic point of view, investing in the development of three-dimensional grating manufacturing processes and new forms of finishing that would allow us to obtain a final product of premium quality. As a result of our investment, we developed two distinct 3D grating processes: Welded Cobermaster 3D Grating Structurally similar to the traditional grating, with the particularity of being able to take on all types of shapes, whether round, spherical, conical or others. It is a type of grating that allows us to produce small and large three-dimensional pieces, combining design with exceptional structural performance. This type of grating is ideal for applications such as: three-dimensional facades, counters, wine racks, partitions, large sculptures, stairs, fences with round contours, retail solutions, among others. ROCKET – 3D Grating Sculpture 3D Grating Cube Display SPIDER Ceiling Lamp Not Welded Cobermaster 3D Grating This is a type of grating built using a completely innovative process without the need for welding. The entire structure is assembled using a fitting and crimping system developed by Cobermaster, and is not subject to warping and imperfections caused by traditional welding processes. We are talking about a type of railing that presents millimetric perfection, ideal for manufacturing all types of furniture among other applications in the area of architecture and interior decoration. Our three-dimensional grid is patented and its application in decorative elements is protected in several dozen countries. STUDIO – Candeeiro de Pé ANGLE – Mesas de Centro PURITY – Mesa de Escritório Artigo anterior

Three-Dimensional Grating Read More »